If you anchor often enough a time will occur when your yacht is brought up abruptly against the hold of your chain and anchor. Initially it might be a gentle bump but, as the wind increases, it can become quite aggressive and frightening.

Snatching at anchor is debilitating for crew and, at worst, is probably the most common cause of an anchor dragging. So minimising the effect is beneficial.

It is not only wind that causes this snatch loading. Commonly as the wind increases, the wave action, especially in anchorages with a bit of fetch, also increases. You only need a gust coinciding with a peak wave and a swell at high tide when your scope is at its lowest and you have a classic dragging situation.

Historically there were a number of solutions – the easiest of which was deploy more chain. Another solution, not seen much today, is a riding sail, which reduces veering, historically quite common on ketches and quite feasible on any monohull (See CH March 2015).

Another option is available and that is to use heavier chain. Certainly heavier chain is advantageous up to a point but, if you upgrade your chain, you will need a new gypsy and as soon as you discover how much that costs your enthusiasm may be tempered. Moreover, upgrading from, say, 100 metres of eight millimetre chain to 100m of 10mm chain will add an additional 100 kilograms to your bow locker. Might be good for catenary, but it will do nothing for your windward sailing performance; especially if you have a modern lightweight yacht, affectionately called ‘AWBs’: average white boats. Weight in the bow is a very real issue and this article is mostly, but not exclusively, for them.

There are other disadvantages to increasing chain size, besides the money and the weight: you will need a more powerful windlass, heavier and expensive; it will need more power so a bigger battery or battery bank; and it will need heavier power cables. All of this adds up to even more money. Moreover, bigger chain takes up more room, decreasing the space in your bow locker and furthering the potential for increased frequency of towering.

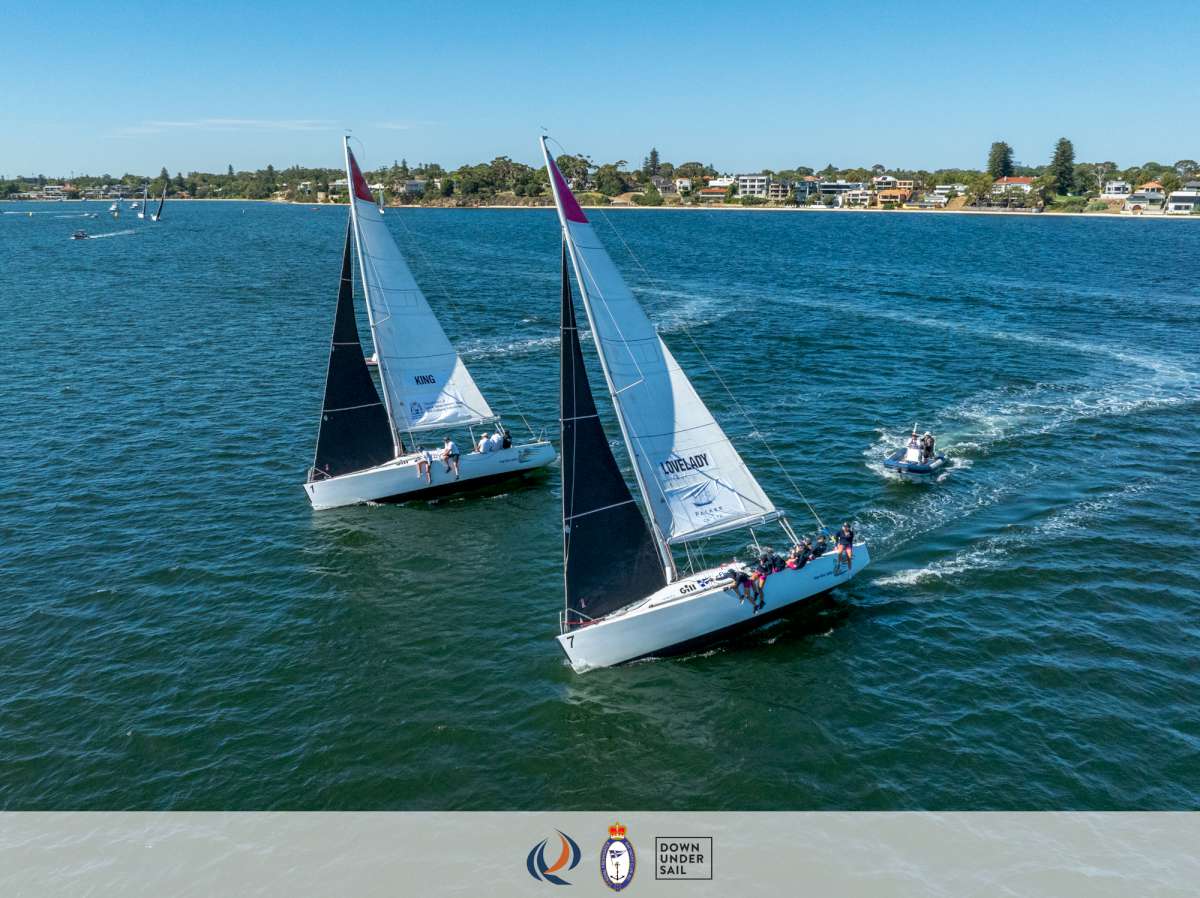

One useful option is to anchor in a ‘V’. Without entering a discourse on anchor size, you should carry spare anchors such that they are suitably sized to be a primary if necessary. If conditions are concerning you should make every and any opportunity to deploy a second anchor, whatever size your primary anchor might be. Why carry a spare if you are not prepared to use it? There is nothing wrong with belt and braces.

Deploying a second anchor reduces veering, in the same way a bridle of a catamaran reduces veering. Veering directly impacts the tension direction of your anchor. Any constant changes in direction associated with the chain lifting and falling, reduces the shear strength of the soil in which your anchor is embedded. These are not illusory conclusions, but those of both the United States and United Kingdom navies who have documented the effects.

Reliance on one anchor means all your eggs are in one basket. If you use two anchors you both reduce veering but also reduce the risk of your only anchor catching something foreign in its toe: oyster shell, beer can, waterlogged piece of wood; a reason for even modern anchors to drag.

It merits mention: reports of dragging of modern anchors are very limited and commonly have nothing to do with the anchor per se. Often the anchor was the wrong type to use in the specific seabed. Fortress, for example, are exceptional in soft mud, mud and sand; but very average in medium density weed or stony anchorages. Spade are good in weed and cobbles, though only a Fisherman’s works, to a point, in heavy weed; but Spade is pretty unexceptional in thin mud.

So dragging of modern anchors does occur but more due to poor choice rather than a poor anchor. Invariably, when an anchor does not perform as anticipated, it is commonly found that an apparently insignificant object, such as a bit of wood, is impaled on the toe.

Why use chain at all?

For one: it works. To a point but it has stood the test of time. Prior to, say, 1970 the only commercially sensible alternative was galvanised wire or a natural fibre rope.

Another major reason for using chain, in addition to the benefits of catenary, are its abrasion resistance for which it currently stands head and shoulders above anything else. Coral and to a lesser extent rock, has a voracious appetite for conventional cordage and could eat through it overnight. Wire is an option and is accepted by classification societies, but needs to be retired to a schedule as it suffers from difficult to detect internal failures, whether stainless or galvanised. Swages are also an issue as they are prone to failure.

Another alternative is Dyneema. It is used by the oil industry as an anchor rode; it is very abrasion resistant but floats, making it a major hazard for propellors and keels. Dyneema might appear far-fetched but there are trials with short, 3m to 5m, leaders of Dyneema between anchor and chain and as soft shackles to join anchor to chain.

Consequently, despite being very 19th or 20th century, galvanised chain has real and significant technical advantage over the alternatives.

If weight in the bow is disadvantageous why do we use such heavy chain? There are two reasons, the first reason is strength. At the time and in the absence of anything stronger ‘bog standard’ chain was made decades ago from 200 megapascal steel. Later, as steel making technology progressed, it went to 300MPa steel. The advent of cheap, reliable, high tensile, 1,000MPa chain is relatively recent, think of the last decade; so it has not really surfaced for the leisure marine industry.

Computation of chain size diameter versus chain strength is simple. Based on strength and windage we have spreadsheets that have been developed over decades resulting in the recommendations we see today.

These have proven more than adequate, basically there appears to be a sufficiently high safety margin that chain might actually be well over-specified. We are not suggesting change, but buy correctly-sized, brand named chain and it will be bullet proof. The best insurance policy!.

High tensile chain has only been commonly available since the 1970s and galvanised high tensile chain (G70) was only available from Peerless in America in imperial sizes, which really limited sales to America. This has changed in the last couple of years as Peerless now make metric sizes.

PWB is now part of Kito, Japan, the same company owning Peerless. It is possible PWB may consider holding Peerless’ metric G70 in stock.

Maggi, from Italy and sold through Chains, Ropes and Anchors (CRA) in New Zealand, have entered the G70 market with metric and imperial sizes. The fact that CRA markets and sells into Australia suggests a market niche that PWB could address.

Galvanised high tensile (G70) anchor chain has been used for decades, advocated by Dashew since the 1970s, it is hardly new! Although it has always been peripheral, though now with growth in sales, there were unsubstantiated reports of failure through hydrogen embrittlement and some internet scaremongering that it was so brittle it snapped like glass.

There have also been questions over the quality of some G70 galvanising, which has nothing whatsoever to do with HT chains as the quality issues are also evident with G40 chain. These tales of woe have been a discouragement. Use of even stronger grades: G80 and G100 (see the article in CH November 2016), is recent and now possible through new methods of galvanising; Armorgalv being only one of a few similar processes, Sherardizing and Greencote being others though Armorgalv is the only alternative to HDG in Australia.

On the horizon it is possible that a 6mm x G100, Armorgalv coated chain can be produced with the strength of a traditionally galvanised 10mm x G30 chain. This would offer the opportunity to carry a 100m rode weighing 80kg instead of 100m weighing 230kg. Replacing 10mm with 6mm would seriously free up bow locker space.

For a designer this offers opportunity to better use that bow space or, possibly, move the chain locker nearer the mast. This is getting close to a kryptonite piano wire rode. Unfortunately, some might say fortunately, G100 in terms of strength and 6mm, in terms of size, is the current limit. G120 will not fit a windlass gypsy, it is the strongest chain currently available and 6mm is the smallest available.

One reason for heavy chain was to ensure the tension on the anchor was applied so as to be as near horizontal as possible. A few degrees above horizontal was thought to be acceptable but anything beyond 10 degrees was considered dangerous. Most modern anchors with their ability to bury and bury chain has reduced the importance of this imperative as the tension angle, the angle of the buried shackle, can commonly be much higher and independent of the angle of the chain at the surface.

It is an extreme example but, using US Navy anchor rode prediction programmes, it has been calculated that during the testing of an FX37 Fortress anchor in soft mud with the flukes set at 45° and the fluke at just under 1m deep in the seabed the rode/seabed angle was 12.1° (5:1) and shackle angle 35.9° and at a different scope (6.5:1) the rode/seabed angle was 9.1° and shackle angle 35.4° and the anchor set well.

Continued and increased tension, to 930kg, to the anchor (at 5:1 scope) drove the anchor more deeply to 3.5m, the rode/seabed angle rose to 15.2° and the shackle angle to 49.7°. Basically the tension angle imposed by the shackle is well outside 10° (35.9°, 35.4°, and 49.7° respectively) and totally independent of the rode/seabed angle (9o to 15°). Yet the anchor works perfectly, even though the tension is above 35° to the horizontal.

This simply underlines that most modern anchors work differently but more efficiently than earlier models and historic experiences may no longer be valid. One conclusion: question dogma!

Without implying the need for destructive debate on anchor choice, our ‘catchall’ word ‘most’ covers: Rocna, Supreme, Excel, Spade, Ultra, SARCA, Kobra and Fortress. These are anchors we have tested and, if correctly sized, they do dive, so burying chain. We are not implying they are all perfect and other anchors might dive, but we have not tested them. When our anchors are set in clean sand, they are usually completely buried along with at least 3m of chain.

The other major reason for use of heavy chain has been the cult of catenary, the idea that catenary is the only way to minimise shock loading. There is no doubt that catenary, that sag in a long length of chain, does offer a way to minimise, or remove completely, snatch loading. But catenary is only successful in certain circumstances.

The big problems are:

-

you only carry a finite length of chain

-

wind might be finite but its top limits are higher than your ability to deploy more chain

-

the weight of chain is fixed, you either have 6mm or 8mm or 10mm etc., you cannot increase the weight according to conditions

-

there may not be room to deploy more chain, the anchorage might be small or full of other yachts

-

at around 30 knots catenary effectiveness disappears, beyond 30kt you are effectively moored with an inelastic steel connector.

Some basics

Commonly a 35’ to 40’ yacht, the sort that most of us can buy: Beneteau, Bavaria, Hanse, all AWBs, would carry 8mm chain. Deploying 30m of chain with 6m between bow roller and seabed, giving a 5:1 scope, would not be uncommon.

In 20 knots of wind all of that chain will be off the seabed, so its ‘all’ catenary. Dive on your anchor in 20 knots of wind and, as your yacht swings, you will find if you touch any exposed part of your anchor that the anchor moves with every movement of the chain. Dive on your anchor in 30 knots, when the chain is as good as straight and you will find that the anchor movement is surprisingly aggressive.

A moving anchor ‘liquefies’ the seabed in its immediate proximity and the shear stresses holding it in place are reduced. A shallow set anchor, think old fashioned, badly-designed or incorrectly sized, is liable to break free and drag. To minimise these effects the anchor should be deep set with as much chain buried as possible since buried chain is also subject to friction within the seabed, which protects the anchor from chain movement effects.

Smaller sized chain is easier to bury than larger sizes. Tests show in sand it is not much, but moving down on size from 10mm to 8mm chain will allow your anchor to dive approximately 5 per cent deeper. Though this seems small the shear strength that is holding your anchor in place increases in strength with the square of depth. A 5% increase in depth is a 10% increase in hold: a good return. Furthermore an overly large anchor is difficult to deep set and more so with a big swivel and big chain.

You can deep set a big anchor, bigger than might be recommended. To deep set a big anchor you need large engine power, larger than would be commonly found in an auxiliary engine of an AWB. Or you need lots of wind, in a constant direction.

An aside, CH developed a self righting device, called a Boomerang, that ensures your anchor self rights at the bow roller during retrieval. For details google ‘Yaffa Boomerang your anchor right back’. If made as suggested the Boomerang is thinner, has a smaller cross-sectional area, than the chain and this slightly enhances the ability of your rode to bury. Moreover, because the Boomerang has vertical area, much greater than the chain, it resists veering forces when fully buried and thus enhances anchor performance, this has been tested independently.

Interestingly Bruce, now makers of oil rig anchors, make devices called Boosters that act a bit like an aircraft aileron and help pull the chain into the seabed, the boosters are like downward pointing vanes on the rode. The concept cannot be used, or not yet, on our rodes as the Boosters would be too wide for our bow rollers. But these boosters similarly enhance rode performance, similar to the Boomerang, so the idea of modifying rode performance is not original!

Chain on the seabed has the advantage of friction between chain and seabed. So chain on the seabed reduces the impact of chain on anchor.

Deploy more chain, so as to get it on the seabed if you have room and more chain. Or use a snubber as it also keeps more of it on the seabed for longer because the snubber and catenary share tension, so the positives of catenary last longer.

The word ‘snubber’ has been used to describe two similar pieces of cordage. Snubber is used to describe a short length of cordage attached to the chain and to a strong point on the yacht with the primary reason being to take load off the windlass and to stop the chain rattling on the

bow roller.

It is critical to ensure snatch loads are not placed on the windlass and this is what the cordage successfully does for the first meaning of the word. Windlass are not designed to take snatch loads; nor might the deck, to which the windlass is attached, have the strength to take those same snatch loads.

In testing for snatch loads the largest load we found was between 650kg and 700kg. This would all be imposed on the windlass and its reinforcing if there was no snubber. Windlass are meant to be able to lift all the chain and anchor, in our case around 150kg/200kg, well below the snatch load. It is unlikely the designer and builder of the yacht and windlass will have catered for a load three times the lifting limit of the windlass.

A short snubber could be wire, Dyneema or nylon and has virtually no elasticity and simply acts like the chain.

The second application of the word is to describe a long piece of cordage that cushions the yacht from snatch loading, a bit like the suspension on a car or a bungy cord on a bungy jump. Nylon stretches about 40% at break but about 10% is considered the safe working load limit (WLL), though stretching upto 20% occasionally is acceptable.

A 10% stretch is roughly equal to 25% of minimum break strength and nylon ropes are rated at a 4:1 safety factor. The higher the stretch, percentage wise, and/or the more cycles above 10%, the shorter the snubber life.

The elasticity of nylon is a function of weight: the thinner (i.e. less weight) the easier it will stretch. By measuring weight per metre it is possible to calculate extension.

Nylon is not the only cordage you can use as a snubber, an alternative is polyester. Polyester is suitable but lacks the degree of elasticity of nylon, so you need longer lengths to achieve the same performance. In the unlikely event you cannot source nylon then polyester is an alternative, but nylon is the most suitable.

The elasticity of nylon is approximately linear: double tension and you double the amount of stretch. For the purists, stretch increases faster as tension increases; but this difference for our application is academic rather than practical.

Snatch loads are all about energy: energy of the moving yacht, kinetic energy. Energy is measured in joules and is defined as:

Joules = (mass (kg)/2) x (velocity (m/sec))²

Therefore, a 45’ x 12 ton yacht (12,000kg) moving at 1 knot (0.5m/sec) = (12,000/2) x 0.5². Thus, 6,000 x 0.25 = 1,500 joules.

We do not know how fast a yacht moves at anchor, our equipment is insufficiently sensitive. But one knot seems a reasonable figure; it might be higher for a flighty smaller yacht with a fin keel or lower for a heavier displacement, longer-keeled yacht.

Energy is based on the assumption that the yacht veers. We did some tests on rode tensions and found that the maximum loads occurred as a result of veering, not windage per se. In fact snatch loads, as a result of veering, are at least two times the average load. So a yacht that is in an anchorage and does not veer will have a lower maximum tension in the rode than the same yacht in an anchorage where the yacht veers.

Wind veers in most anchorages, even very sheltered anchorages can be subject to strong bullets of wind from unpredictable directions. We want to consider veering as a worst case scenario.

If the yacht is attached to the anchor with a piece of kryptonite steel piano wire then any energy is transferred directly to the anchor, a snatch load with no catenary, no friction on the seabed that will modify the shear strength of the seabed in which the anchor is embedded.

Sticking with our example of our anchor attached with kryptonite piano wire we could transfer that energy to something elastic, in the same way that the impact of bumps on the road are transferred to our suspension or old fashioned springs. If we had this mixed rode the Kryptonite would give us abrasion resistance and strength, the elastic component would absorb energy. Think of the bungy jumper, at the bottom of their fall they feel almost no shock load just a gentle deceleration. Think of a snubber as bungy cord for a yacht.

It is possible to calculate the amount of energy that can be absorbed (potential energy) by nylon, but, fortunately, Marlow Ropes have made the calculation for us, see Table 1.

A 12mm x 10m length of nylon will comfortably absorb almost 1,500 (1,440) joules, equivalent to about 400kg of tension. Based on measuring rode tensions without a snubber then 400kg of tension is approximately the maximum snatch load developed on a 45’, 7t yacht anchored in 30 knots with a 5:1 scope using only chain as the rode. 400kg is 7.5% of ultimate tensile strength (UTS) of 12mm nylon.

Consequently, if you are using a kryptonite piano wire rode so totally inelastic and no catenary effect, then a 10m length of 12mm nylon cordage will absorb all of the energy developed from snatch loading at 30 knots of a 45’ yacht and work at below the recommended limit of the WLL of 10m of 12mm nylon. If you double the length of nylon to 20m the energy absorption will be the same, i.e. 1,500 joules, but you will only be working with 3.75% extension, so well below the working load limit.